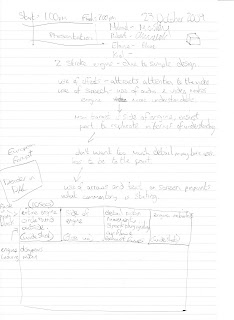

Wednesday, 9 December 2009

Complete (week11-12)

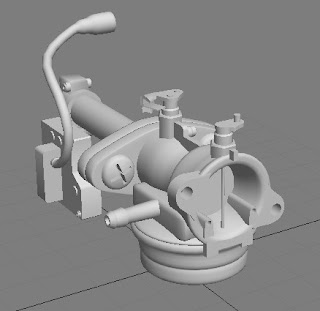

Finally, I decided to use 3DS MAX software to do this model. I spent a lot of time, but I found that I can use the components which are completed before to make a new components. This is saved a lot of time. Through the production of Carburetor, I learned some new knowledge. When I made another model “Lawnmower”, I feel easier. At the same time, the production of methods is similar with Carburetor. When I finished the model, the modification is very important in this work. A good model is rely on modify rather than made out. So I spent a lot of time in this part. In general, the effect of the final model is still good.

When we do the animation, I have been listened the views of groups members carefully and seriously, look at how to do this animation. Because animation is not my strong point, so I have a lot of knowledge to consult our group members. When our group members do the animation, I always observed their methods and then research it after class. So I learned lots of technologies. This is the greatest benefit in this group work. Overall, this group work is great helpful to me. I have learned lots of new technology and knowledge.

Animation (week10-11)

Sunday, 6 December 2009

Create Lawnmower

when I made the wheels, I think my approach is relatively cumbersome, I have been looking for a good production methods, but it has not success. So I can only use this method. Despite spending a lot of time to complete these components, but the results was pretty good. First, create a Torus, and then converted to editable poly, select points, to modify. There is the more trouble in the editing process. The photograph of the wheel texture is not very clear, so I found a wheel picture from the Internet. According to photographs I made the model is becoming much easier. This method is required patience, it spent a lot of time to adjust the location of vertexes, but the result is very good. The method of connect the wheel’s components is similar with Carburetor. Create Cylinder and modify the model to reach the final effects.

The model is mainly divided into several parts, first make a few basic models, and then adjust points to reach the final effects, finally make the model become smooth.

The final step is making some small components. When it finished the model, the modification is very important. In a separate production of the components, there are some parts are not match with the photo. It must be through the adjustment to be completed. First I added a Meshsmooth modifier to become smooth of the model. Then Observation, which areas is still not match with the photo. Then quit the Meshsmooth to adjust point position. Through repeated conditioning, the final match to meet the basic and photos. The same method, adjust the various parts of models. When I completed of model, I sent the model for my group members, finally we decided to put 2 stroke engine models on the Lawnmower, and then make another part of the animation.

Monday, 30 November 2009

Group meeting 4 and 5(week 9)

The second meeting we decided to make a lawnmower model .Finally, we will put the 2 stroke engine on the lawnmower model, and then continue to do our animation. I am responsible for do the lawnmower model. On the other hand, other group members began to record voices and make the model map, simple animation. Next week the group will focus on animating the Piston, animating the fluid movement within the engine.

Create Carbureto(week 8)

I repeat do this part a lot of times because I hope to find a suitable way to make this a part .By the end, I decided to use the Lathe process to make this part. First, I observed of photos, used the line to drawn the cross-section diagram of this part. Then add a modifier is the Lathe, modify the parameters, raise segments and press Mix button. Then it was converted to editable poly, select the vertex to adjust, remove the Cap, finally, and add a modifier is the Meshsmooth. Now, this section is complete. In the production of this part, there are some problems. When I draw the cross-section, I always do not know how to paint it. I repeated many times. Finally I got good results.

>

>  > Compound objects> Boolean, select a copy mode, and then click the

> Compound objects> Boolean, select a copy mode, and then click the  pick up box, and then adjust the control panel in the parameter calculations. Access to modify panel to modified. Then copy a screw.

pick up box, and then adjust the control panel in the parameter calculations. Access to modify panel to modified. Then copy a screw.

Create tubes

First, I created a Cylinder, modify the parameter

converted to editable poly, select point, through the select and rotate, select and move, select and uniform scale, and adjust the tube position. And then create a 3 Cylinder, making the top of the tube, methods and the same as before. The effect is shown in picture.

converted to editable poly, select point, through the select and rotate, select and move, select and uniform scale, and adjust the tube position. And then create a 3 Cylinder, making the top of the tube, methods and the same as before. The effect is shown in picture.

Sunday, 29 November 2009

Preparation (week 7)

Group meeting3(week 6)

Thursday, 22 October 2009

Summary

Although the final works were not achieved the desired effect, but it is still to complete this work. If I had more time to learn production techniques, and accumulated enough experience, I believe I will do it better.

Wednesday, 21 October 2009

creat hair

Statement: create hair I was using the 3DS MAX 8.0, this version provides a hair and fur system. Head model I was using the 3DS MAX 9.0 software to build it.

Tuesday, 20 October 2009

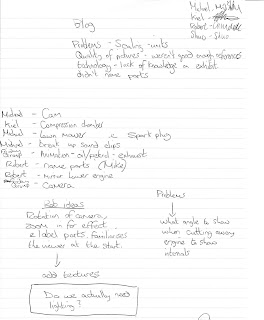

group meeting notes

Once created the group would then have to look into produce:

- Textures

- Lighting

- Camera work

- Animation

On 23th oct ,we will continue to discuss the work of each member needs to be done, and the production process.

uvw mapping

, but some points still get together, so I need to put each point to the appropriate place. The next step is to export the UV map out of the 3D max software, converted to. tif format files into the photoshop software for mapping. This is a very complex task. First, I looked several times repeated tutorials and found a few more crucial part. Then I began to make the map. In the process because of his lack of experience, the UV map is a flat, while the photos are different from it. So I always can not find the exact location. But through the constant adjustment, get the final result.

creating a nose,mouth,ear and back of the head

Create ear

I followed the video to learn to do ear model, but in the end I did not finish it. The problem I found is that I started concentrating too much on what the ear in the tutorial looks like. And some areas I do not quite understand what to do. Then I changed methods. First, the establishment of a rectangular box, converted to poly. Then I add a curve in the space. This curve should conform to the ear shape, and then continue to edit, at the modify command of modify, click the create shape from selection button and then select the pick line, at just pick up the curve, with the extrude command, and then adjust the location of points. Then I used cut command to add the lines, continue to adjust the location of points. Finally add a Mesh smooth command.

Create a sphere ,this sphere has to be of the same size to the face. Using the scale tool, I scaled the sphere to make it round the head shaped. After this, I changed the rectangular selection tool to paint selection. and then, holding down the ctrl key, choose not to be used place, and then delete. The next step was to delete the right side of the sphere and then to adjust points. The next step is mirror, the separation point welded together. And then continued to made neck. Through the copy the edge and regulation of points. Production method is similar with method of made the mouth. When I begin to make back of the head and neck, the problem is how to make a smooth surface. I choose to cut lines and then adjust point. Ultimately achieve the desired results.

Thursday, 8 October 2009

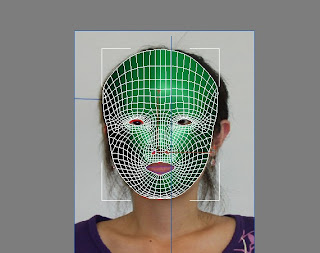

3D face

The main task of this week is to create the character's face model. Firstly, in the 3D MAX, Select front view, create lines, according a good wiring diagram of the picture painted to create lines. After it, select one of the closed frame into editable poly and then select the attach all of the lines add together. To welded to the separation of vertex. But in the welding process, some points are not welded, so I chose to use target welding method to weld point.This process must be avoided the triangle in order to facilitate the adjustment point position. Then go to the left view, based on the facial structure of the photo will adjust to the right position. This process is the very important and spent lots of time but also some areas in need of careful. I must carefully adjust the location of every point. Turning to perspective, and then continue to adjust each point.

The next step is to complete the face model to make it. It can be achieved in two ways, one is a mirror, and another is to add a Symmetry Modifier. At first I use the mirror, but when the mirror finished, there are some problems that I discovered there are some points not in conformity with the location of photos and some points can not be welded together, so the ultimate effect of this method can not be achieved, I chose another method to add a Symmetry Modifier. The benefits of this method is that if I found something was wrong I can delete and re-do at the same time, this method can also be easily adjusted to point to the appropriate location of the photo.